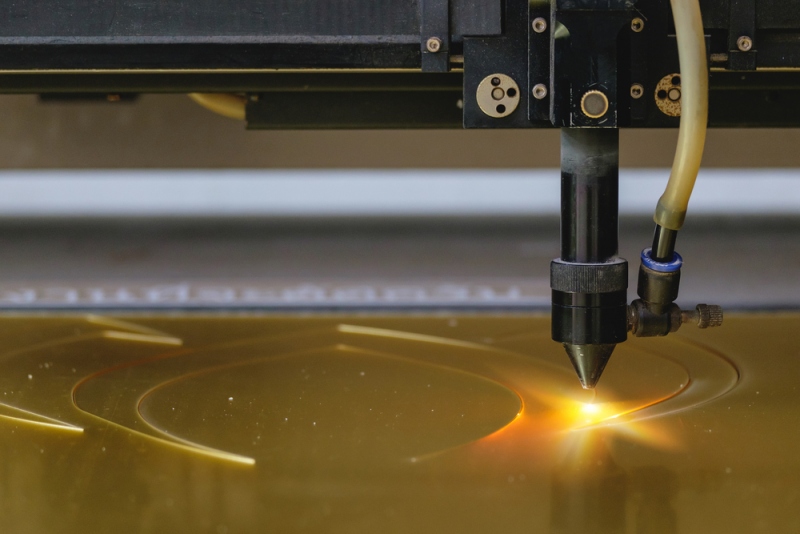

Laser marking on plastics : LASIT has a wide range of laser engraving machines, including CO2, fiber, green laser and UV solutions, which offer permanent marking, resulting in perfect traceability for all types of plastic materials.

Laser marking has completely replaced screen printing in the production of pieces used in so-called “day & night” applications.

In fact, with the laser, it is possible to have perfect control over the quantity of removed material and thus the depth of engraving as well as being able to perfectly define the size of engraved lines and improve definition in the corners. This results in enhanced appearance and, most of all, a significant increase in productivity.

With the “Parameter Test” function in FlyCAD, the software automatically changes two out of three parameters (frequency – speed – power ) and carries out a marking cycle with the chosen parameters in matrix form.

From the analysis of the marked matrix, one can see and choose the best example of laser marking and use that to select the necessary parameters.

The dynamic Z axis is characterized by a system of lenses installed on a linear motor. It allows for perfect and constant laser beam concentration across the entire area to be marked.

This system also allows for moving the laser’s focus without moving it along the Z axis.

Focusing with the dynamic Z is a necessary tool for laser marking on different levels of plastic details.

Many plastic materials can be laser marked via what is known as the “foaming” process.

In the foaming process, the laser beam melts the plastic surface and then creates small gas bubbles on the material after it cools down.

Afterward, the gas that has accumulated inside increases the volume of the material. The part that has been laser marked appears to be upraised.

Leave a Reply