In the event of buying chemical pumps for dispensing the correct amount of elements for the procedures, industries must purchase from a reliable company that provides the best pumping solutions. Now all operations can be expanded with the efficient chemical metering structures along with chemical solution hoses, mounting brackets, and tanks. Obtain the best metering pump that can withstand scathing materials or else flow indicators and replacement valves are also helpful for keeping the metering pump disburse just like new. Repairing and installation services are also provided by the companies selling these products. From the Internet, several reliable names can be found.

Importance of Maintenance

An essential portion of all chemical processing businesses is known to be Chemical pumps. Thus, reliable operation from these pumps is expected all the time. Also, these include the capacity of handling numerous corrosive materials. If not maintained in the proper manner, the pumps won’t function properly that will hinder the entire production process. From time to time, these must be preserved. These versatile pumps can efficiently handle any modification in the ambient temperature, humidity or viscosity of the fluid. This means that maintenance is a must otherwise these changes cannot be handled efficiently by these pumps.

Naming the Characteristics

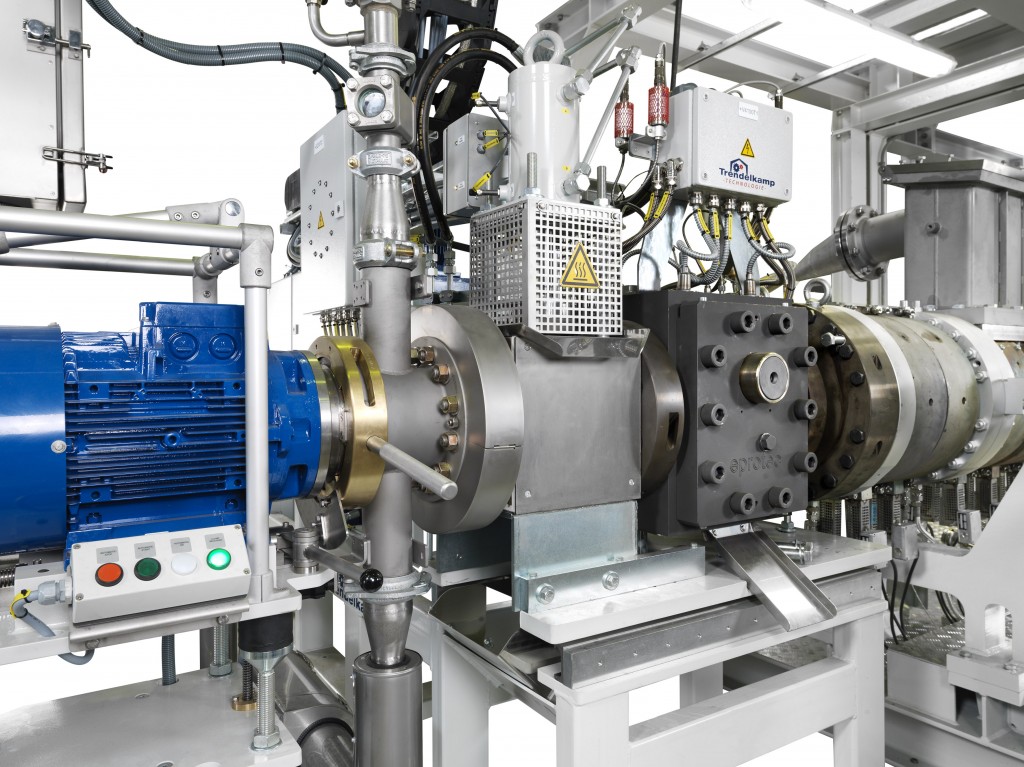

Due to the availability of various features, Chemical pumps are widely utilized in the entire chemical industry. Firstly, these are typically used pumps that are versatile. Secondly, these include a rotating impeller that passes on the kinetic energy to the fluid that is being pumped. When the liquid is left by the impeller, the speed of the pump slows down by several other stationary parts. The kinetic power then gets transformed into pressure energy. Chemical pumps have the capacity of adapting to periodic changes. Any transformations in the features of the fluid being pumped and piping along with sharp bends can be handled by these pumps.

The Various Applications

Pumping, metering, transferring of fluid chemicals and circulating are few of the important applications of Chemical pumps. These have the ability to handle a broad array of viscosities at low and high temperatures. The capacities include ml/hr to m3/min and up to 170 bars pressure can be discharged by these pumps. Run dry and as well as self-priming chemical pumps are available that are offered by numerous firms offering pumping solutions at competitive prices. Selecting the correct pump is crucial for conducting all the operations in the right manner. Pick the most top-rated company for buying these.